WOOLLY Machinery

woolley

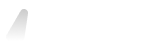

Tube Production Line

Woolley provide Mono-layer, 2-layer, 3-layer, 5-layer, 6-layers tube extrusion machine,offer tailored service

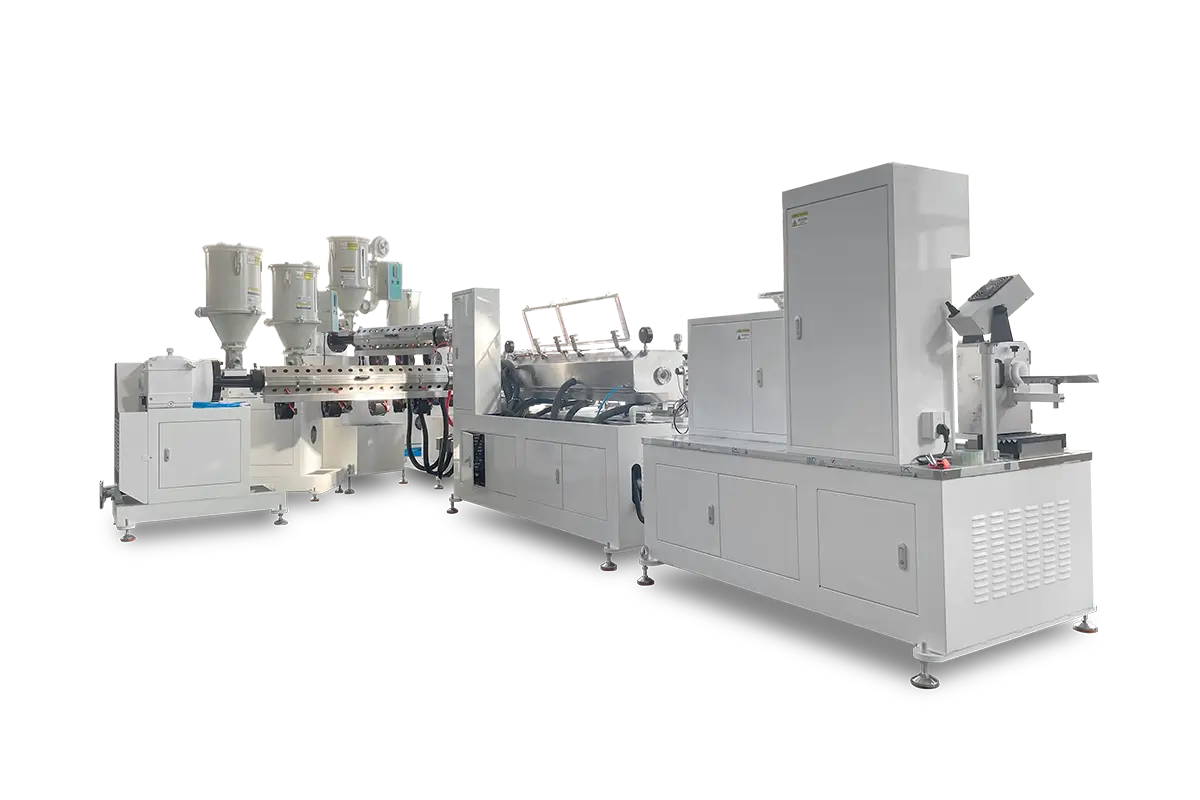

Wooley JX-LM150 laminated tube machine can make ABL/PBL tubes, It has stable traction speed with fully automatic servo response

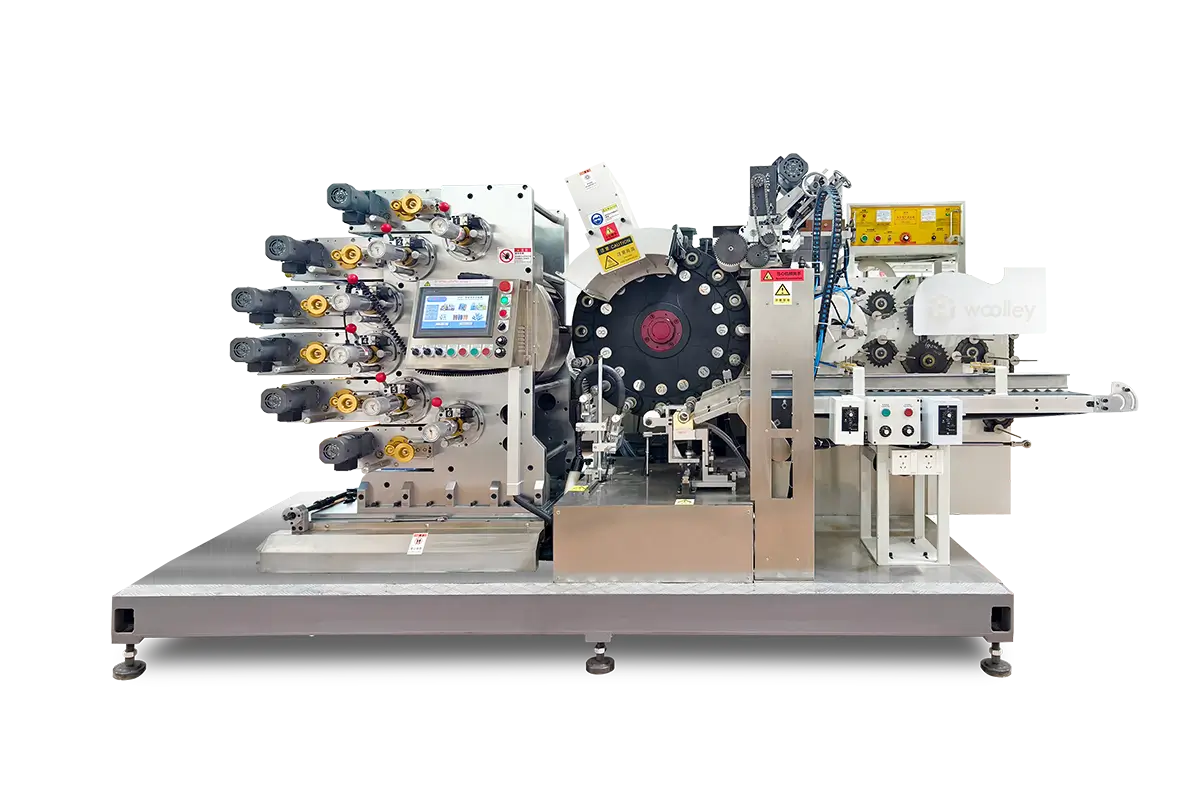

High-speed printing (80pcs/min), durable guide rail slider, compact UV oven, automated ink adjustment, intuitive interface

High-speed printing (80pcs/min), durable guide rail slider, compact UV oven, automated ink adjustment, intuitive interface

Woolley’s Super-Star Header Machine JX-HS120B, owns updated patent tech., features reliable two-plate mold structure

JX-HS70 innovatively adopts a vertically upward heading technology method, by compression molding processfor PE material spraying

The machine is driven and controlled by the most advanced servo mechanism, especially for the quantitative dripping/spraying and high-pressure compressing/shaping process

Woolley’s Versatile automatic capping and foiling machine for plastic tubes, Accomplishes capping, top-sealing, with optional orientation and drilling

1~9 colors stations optional, automatically processes very well for transferring a stencilled design onto a surface using a mesh screen

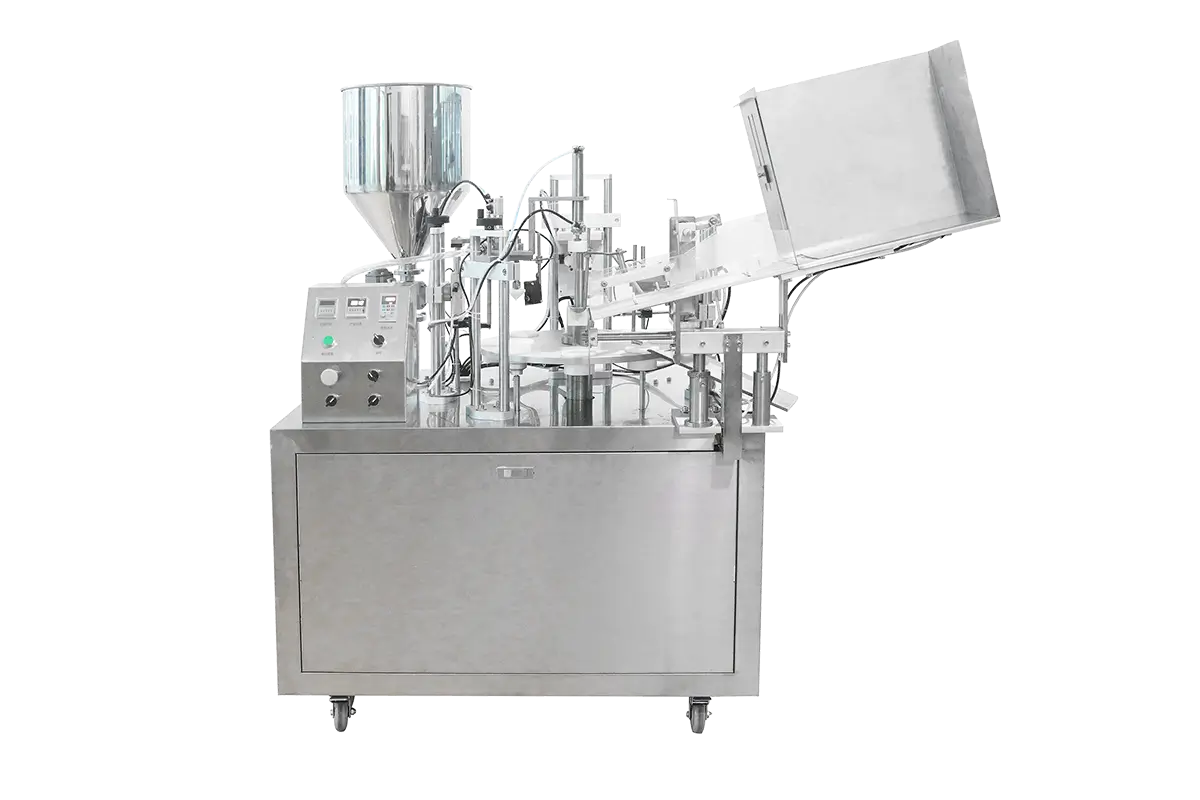

The machines are highly automated to fill various liquid, paste or semi-solid materials into tubular containers and complete the sealing process

Excels in high automation, precise sorting, and adaptability. It can connect tube body making machine, to realize full automatic production line.

Equipped with dual robot arms. It’s full automation, precise sorting, and adaptability. It has vibrator management and loading robot

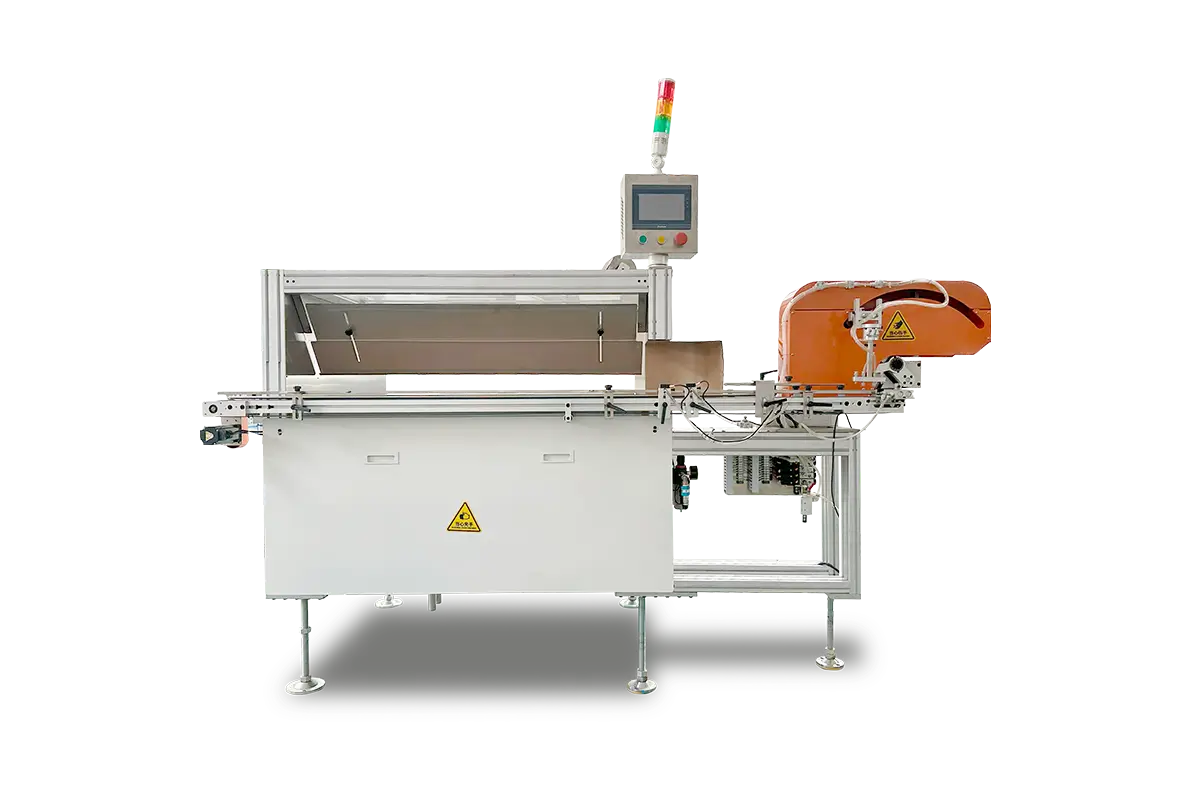

The Woolley packaging machine delivers seamless automation for tube, can, and bottle packaging, including automatic boxing, cartoning, carton changing, and sealing

Need Help?

Ready to speak with a Woolley team member? Contact us today.